KNIFE CARE

All F. DICK knives deserve special care and attention when it comes to maintenance. Proper knife care is crucial. Knives that are forged or have a wooden handle should never be cleaned in the dishwasher. Knives with plastic handles are completely dishwasher safe; however cleaning in a dishwasher is much more aggressive than washing by hand.

The use of highly concentrated detergents, leaving the knives in hot steam for a long time and also the presence of certain food residues can lead to pitting on the blades or even corrosion. We recommend clean the knife by hand with a soft cloth and a mild alkaline detergent. Wipe your knife after cleaning to ensure that tit is thoroughly dry – this will prevent any pitting on the blade. You can occasionally maintain knives with wooden handles with food-safe oils (e.g. olive oil). The oil makes the handle nice and smooth and prevents shrinkage and cracks.

PROFESSIONAL KNIFE STORAGE

For your safety and to protect the cutting edges of the blades, we recommend that you store the knives in a suitable knife block or on a magnetic rail. When buying a knife block, make sure you buy one with enough space and horizontal slots to protect the knife blades. We recommend our own blade guard for storage in a drawer - Edge Guard. or alternatively, dimensionally accurate compartments built into the drawer.

BLADE GUARD FOR KNIVES

Blade guard – Edge Guard, the special blade guard for storage, especially in drawers. Click here to see the blade guard for blades up to 26 cm.

KNIFE BLOCK FOR KNIVES

Knife block: Knife block with tourne knife, paring knife, boning knife, carving knife, bread knife, chef's knife, meat fork, sharpening steel and kitchen shears.

HOW DO KNIVES STAY SHARP FOR A LONG TIME?

Knives stay sharp for a long time if they are only used for their intended purpose. The knives should only be used for cutting and not chopping. Bones or the like should therefore only be cut with a cleaver.

WOODEN OR PLASTIC CUTTING BASES

Hard surfaces such as stone (e.g. marble) or glass should not be used as a base, as they quickly blunt the knives.

THE ESSENTIALS OF PROPER SHARPENING STEEL CLEANING

The correct and regular cleaning of F. DICK sharpening steels is a basic requirement so that they can be used for as long as possible. It is essential that you clean your sharpening steel to keep it hygienic and bacteria-free, but above all fully functional. Note: incorrect cleaning can lead to rusting and pitting (corrosion) that damages the fine surface initially and even the sharpening steel blade over time. F. DICK sharpening steels are machine-washable, if possible we recommend gentle cleaning by hand using a mild alkaline cleaning agent. Different detergents were tested for their effectiveness and suitability for sharpening steels in practical tests carried out under laboratory conditions – also in cooperation with different detergent manufacturers.

HOW DO I CLEAN THE SHARPENING STEEL CORRECTLY?

Use the correct detergent suitable for metals; never use acidic agents. Do not use detergent that may cause metal corrosion (observe the safety data sheet). Use only a mild, alkaline, basic, chlorine-free detergent. Observe the correct use, temperature, dosage and cleaning time of the detergents. Please note the instructions for use! Do not use additional detergents. After cleaning, it is important to remove all traces of detergent from the sharpening steel. Use the rinse programme on your dishwasher to do this or rinse the sharpening steel thoroughly with water and then dry the steel with a soft, lint-free cloth.

WHAT SHOULD I KEEP IN MIND WHEN CLEANING THE SHARPENING STEEL?

- Only use suitable detergents.

- Do not clean with too high a dosage.

- Do not use acidic detergents.

- Do not clean for longer than the prescribed time.

- Do not leave any traces of the detergent on the sharpening steel.

- Do not expose continuously to high moisture levels.

- Do not expose for too long to fats, proteins and other organic contaminants.

- Rinse the sharpening steel as quickly as possible in the event of contact with spices/cooking salt.

- Do not use metal brushes for cleaning.

STERILIZATION

The short-term use of sterilizers up to a temperature of approx. 120° C is suitable for cleaning your sharpening steel. However, sharpening steels may not be exposed to force that may loosen the handle, e.g. from hanging them up. Sharpening steels have to cool down first before they are used again. The instructions for use supplied by the machine manufacturers must also be observed for the sterilization. We recommend a cleaning temperature of maximum 70° C, then your sharpening steel can be used again immediately.

HOW DO I SHARPEN MY KNIVES PROPERLY ON THE SHARPENING STEEL?

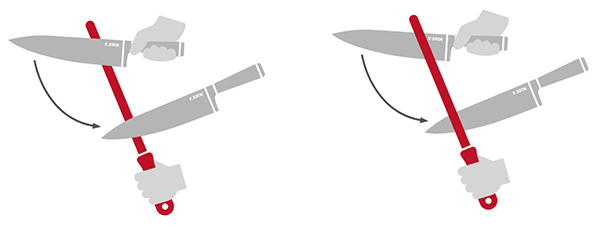

Handling a sharpening steel is not that difficult with a little practice. Place the knife blade at an angle of 15° - 20° on the sharpening steel and slide the blade alternately to the left and right along the steel. It is important to have the same number of sharpening movements on both sides. The sharpening movement has to begin with the end of the knife blade at the tip of the sharpening steel and be guided in a wide arc whilst applying light pressure to ensure that it ends with the tip of the knife close to the sharpening steel handle.

Hold the sharpening steel away from the body at an angle

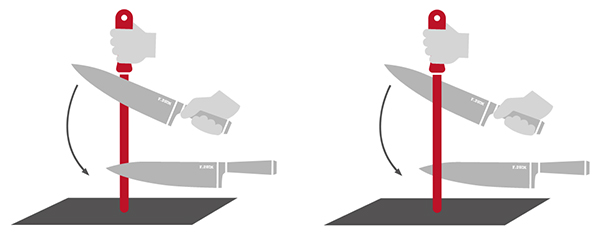

Place the sharpening steel vertically on a surface.

It is important that you alternate the side of the knife that comes into contact with the sharpening steel. You should never first move one side of the knife and then the other side of the knife several times along the sharpening steel, otherwise a curved burr will form towards the other side of the knife, which will remain after the last sharpening movement. However, only a very fine burr forms with alternate sharpening (also known as a thread), which is removed by bending it back and forth. It is vital to apply less and less pressure towards the end of the alternate sharpening movement to ensure that the fine burr becomes weaker and weaker.

OUR TIP

Straighten the cutting edge by frequent, short sharpening before or after each use. Do not wait until you feel that the cutting performance of your knife is poorer.

WHAT ALTERNATIVES ARE THERE TO THE SHARPENING STEEL?

A sharpening steel, whetting stone or sharpening steel alternative can be used for resharpening depending on your personal preference. All types are suitable for European and Asian blade designs. Sharpening tools with hard metal plates or wheels should never be used.

Handling a sharpening steel is time-consuming and difficult for inexperienced people and does not always achieve satisfactory results. As a solution to this problem, Friedr. Dick offers various alternatives to sharpening steels.

HOW DOES AN ALTERNATIVE TO A SHARPENING STEEL WORK?

The handling of the F. Dick sharpening steel alternative will win you over: a simple and safe drawing motion results in an optimum cutting edge. Place the knife on one side of the gap for precise guidance and draw the knife with light pressure and in a curved stroke through the gap in the sharpening unit. The complete cutting edge of the knife is re-sharpened at the same time. Repeat this several times – you will then have a sharp knife with a perfectly formed angle.

Place the knife on one side of the gap. Then, pull through the gap in a curved stroke with light pressure.